Samsung Electro-Mechanics develops high-temperature MLCCs (multilayer ceramic capacitator). The MLCC can be applied to automotive powertrains to target automotive market.

The company made this announcement on 11th of this month. All the 13 types of automotive MLCCs is developed with guaranteed use in a 150 degree Celsius environment with plans to supply them to global auto parts manufactures. This new development will enable Samsung Electro-Mechanics will expand its market share by increasing its product competitiveness with an extended lineup of automotive companies.

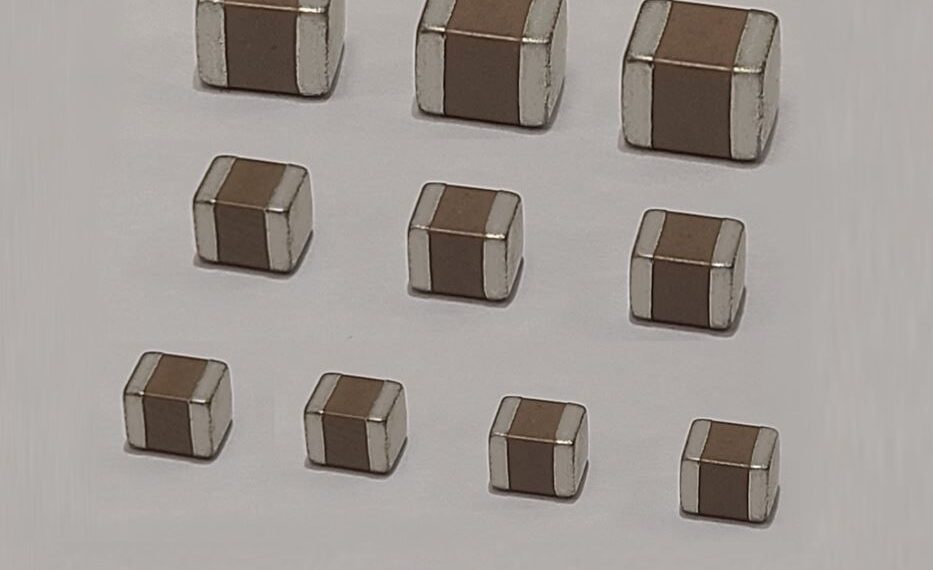

The new products come in various sizes and capacitances, ranging from the 3225 size that is 3.2mm wide and 2.5mm long with a high-capacitance of 22uF (microfarad) to the smaller 1608 size with 220nF (nanofarad).

The Multi-Layer Ceramic Capacitor (MLCC), a core component in electronic devices that controls the stable current flow within electronic circuits, is essential for products such as smartphones, home appliances, and automobiles.

The powertrain requires high reliability for internal components as the internal operating temperature can rise up to 150°C due to high power consumption and heat generation from powering the core driving system of a vehicle, such as the engine of an internal combustion engine (ICE) or the motor of an electric vehicle (EV).

In an environment above the guaranteed temperature, MLCCs tend to lose their capacitance to store energy. In general, 85℃ for IT devices and 125℃ for electric equipment are guaranteed but a 150℃ guarantee is required for the powertrain.

The newly developed MLCCs are capable of normal operation without reduced capacitance even in an extreme environment of 150℃. Due to technical complexities involving raw material development and construction technology, this type of product is currently produced only by a small number of companies.

“Automotive products used in extreme environments are more difficult to develop than products for IT devices, and among them, powertrain applications are the most difficult,” said Kim Dooyoung, head of the Component Solution Unit, Samsung Electro-Mechanics. “Samsung Electro-Mechanics will further expand our presence in the automotive MLCC market by using differentiated materials and manufacturing techniques, such as in-house development of dielectric material.”

The electrification of automobiles has fueled the demand for small-size, high-performance, and high-reliability MLCCs. The automotive MLCC market is projected to grow at a CAGR of 9% in line with the efficient fuel consumption of ICE vehicles and EVs and the increasing number of sensors and electronic control units (ECUs) for motor control.