Electronics firm Sahasra Semiconductors has said it expects to become the first company to set up a memory chip assembly, test and packaging unit in the country and start selling locally-made chips by December.

Sahasra Semiconductors chairman and managing director Amrit Manwani told PTI that the company plans to invest a total of Rs 750 crore in setting up the unit at Bhiwadi in Rajasthan.

“We will invest Rs 150 crore in this financial year for setting up the ATMP facility in Elcina manufacturing cluster in Bhiwadi, Rajasthan. We expect it to be operational by the end of this year. Once the market is established and we touch revenue in the range of Rs 250-300 crore then we will again invest Rs 600 crore. In total, we plan to invest Rs 750 crore initially,” Manwani said.

He said that the first full financial year of the company’s commercial production is expected to generate a revenue of around Rs 50 crore, which is expected to grow to Rs 500 crore by 2025-26.

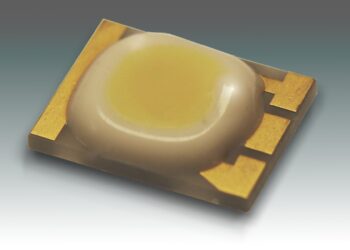

Semiconductors are converted into a complete product ready for sale at ATMP (Assembly, Testing, Marking and Packaging) units. It is the next step after the wafers or chips are produced at a fabrication plant.

Manwani said the company has already invested Rs 60 crore in the current fiscal and by March 2023 it will complete the investment of Rs 75 crore. The remaining Rs 75 crore will be invested in 2023-24.

The company has largely invested in buying equipment and setting up clean room facilities required for semiconductor packaging.

“We expect the first set of equipment to leave from Singapore this week and arrive at our factory by mid-August. Many equipment will come between August and September. We will have trial runs probably in November and we will be able to commercialise production by December of this year,” Manwani said.

Sahasra Semiconductors is one of the companies whose proposal to set up an ATMP unit has been approved under the Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) of production linked incentive scheme.

Manwani said that the company has been in the business of selling semiconductors after importing them but has now decided to plunge in the packaging of the semiconductors due to growth opportunities in the domestic market arising out of government policies, geopolitical situation and concerns around security.

He said that the Sahasra group has sold memory products for a Japanese and a US-based technology companies but after their exit from memory products in India, the company started selling products in its own brand name.

“The demand for memory products is identified. We will not only utilise the semiconductors for our captive consumption but will give out to brands who demand for it. We have been one of the important players in the memory segment. We have been supplying pen drives, SD cards and also solid state drives for the computer segment,” Manvani said.

He said total demand for semiconductors is around Rs 7000-10,000 crore and the company is confident of garnering 5-7 per cent market share by 2025-26.

“There is huge demand coming for domestically made products both from original equipment makers and the retail market. People are looking for domestically made products in the wake of dollar fluctuation, India China stand-off, US-China stand off. People want an alternate source to China. We believe customers will definitely welcome domestically manufactured memory semiconductors,” Manvani said.

He said that locally manufactured memory products will be preferred by companies for security purposes as memory products are also installed in data servers, high-end industrial PCs as well as in communication equipment.

“Both the government and private organisations desire that these things should be locally manufactured,” Manwani said.

(Source: PTI)