The global wafer-level packaging market reached a value of US$ 4.0 Billion in 2021, reports ResearchAndMarkets. Looking forward, the publisher expects the market to reach US$ 11.2 Billion by 2027, exhibiting a CAGR of 18.72% during 2021-2027.

Keeping in mind the uncertainties of COVID-19, we are continuously tracking and evaluating the direct as well as the indirect influence of the pandemic on different end-use industries. These insights are included in the report as a major market contributor.

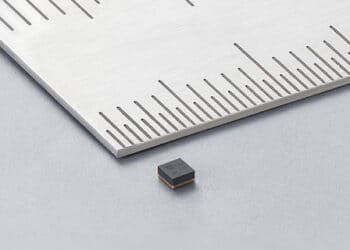

The wafer-level packaging (WLP) refers to a packaging solution used for adding a protective layer of electronic connections and integrated circuits (ICs). It is used for devices, such as microphones, pressure sensors, accelerometers, gyroscopes, capacitors, resistors and transistors.

Some of the commonly used WLP integration types include fan-out (FO), fan-in (FI), flip-chip, 3D FOWLP. These solutions are used at the wafer level of the device, instead of dicing the wafer into the individual die and packaging them.

This offers various benefits, such as a reduction in the size of the wafer chips, streamlining of the manufacturing processes and improvements in chip functionalities. The ultrathin wafers also provide improved heat dissipation and performance, form factor reduction and minimal power consumption.

Significant growth in the electronics industry across the globe represents one of the key factors creating a positive outlook on the market growth. Furthermore, the increasing requirement for more compact and faster consumer electronics is also driving market growth.

This has also enhanced the overall demand for cost-effective and high-performance packaging solutions for enhanced mechanical protection, structural support and extended battery life of the devices. Additionally, various technological advancements, such as the integration of connected devices with the Internet of Things (IoT), are acting as other growth-inducing factors.

For instance, WLP is widely used for the manufacturing of radar systems in self-driving automobiles. It is also used in the healthcare sector for the production of various wearable devices. Other factors, including increasing circuit miniaturization in microelectronic devices, along with extensive research and development (R&D) activities, are anticipated to drive the market further.