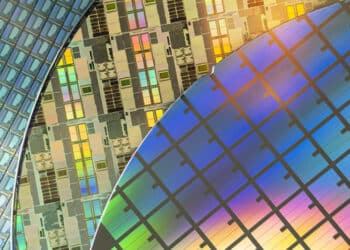

OKI Circuit Technology (OTC), the printed circuit board (PCB) subsidiary of the OKI Group, has announced the development of a 124-layer PCB technology for wafer inspection equipment, aimed at supporting next-generation high bandwidth memory (HBM) used in AI semiconductors.

The newly developed PCB marks a 15% increase in layer count compared to the conventional 108-layer models, while maintaining the same board thickness of 7.6 mm. OTC plans to establish mass production technology for the 124-layer PCB by October 2025 at its Joetsu Plant in Niigata Prefecture, which has an established track record in the production of high-precision, large-format PCBs for semiconductor inspection applications.

The advancement responds to the growing demands of AI processing, which requires the transfer of vast volumes of data between graphics processing unit (GPU) semiconductors and memory components. As semiconductor performance advances, there is a corresponding need for memory with higher speed, frequency, and density. HBM, characterized by its stacked DRAM structure, necessitates more precise and thinner wafer fabrication technologies, increasing performance requirements for inspection equipment PCBs.

In conventional manufacturing, PCB thickness constraints limited designs to 108 layers. OTC addressed these challenges by developing ultra-thin materials, specialized tools, and handling technologies suitable for fragile substrates. The company also introduced a proprietary automated transport system for ultra-thin materials into its production processes, enabling the successful fabrication of 124-layer boards without increasing overall thickness.

OKI has positioned this development as part of its broader electronics manufacturing services (EMS) strategy, focusing on comprehensive manufacturing solutions from design through reliability testing. The company is particularly targeting sectors expected to drive future growth, including AI semiconductors, aerospace, defense, robotics, and next-generation communications.

OKI stated it will continue investing in PCB technologies to meet the evolving needs of industries requiring high-performance electronic components, supporting the ongoing advancement of semiconductor and related technologies.