In an exclusive interview with Electronics Clap, John W. Mitchell, President and CEO of IPC, discusses IPC’s rapid growth in India and the country’s rising influence in the global electronics industry. He credits IPC India’s team for contributing to global standards and highlights India’s advantages, such as its large population, education levels, and infrastructure growth, with Apple’s presence as a sign of progress. Despite these gains, challenges remain in infrastructure and workforce development. Mitchell also stresses the importance of global collaboration, navigating geopolitical tensions, and focusing on sustainable innovation, including the role of AI in advancing efficiency and technology.

Anamika Sahu: Let’s dive right in. Reflecting on our last conversation, what progress has IPC made in India, and how is the collaboration within the electronics industry evolving?

John W. Mitchell: IPC’s growth in India has been nothing short of impressive. Over the past year, we’ve seen a significant increase in membership and active participation from Indian companies. This growth is a testament to the country’s burgeoning role in the global electronics sector. For example, Indian companies have recently played a pivotal role in the development of a new IPC standard within just a year. This rapid development reflects the strong engagement and capability of our Indian partners.

A significant contributor to this progress is Gaurav, who has been leading our efforts locally. His approach to collaboration has been crucial. Building relationships with various stakeholders, from manufacturers to policymakers, has been essential for IPC’s success in India. The depth of engagement and the enthusiasm of Indian businesses have helped propel these advancements.

Anamika: That’s fantastic news. How do you perceive the impact of the Indian government’s initiatives on the electronics industry’s growth?

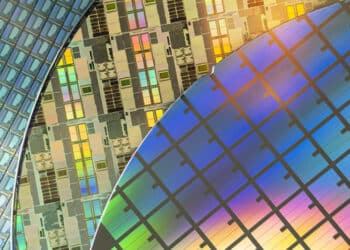

John: The Indian government has been taking commendable steps to bolster the electronics industry. Historically, infrastructure challenges have been a concern, but recent improvements are noteworthy. For instance, the government’s initiatives to encourage foreign investment and the establishment of semiconductor manufacturing facilities have been game-changers.

Apple’s substantial investment in India is a prime example of how these initiatives are paying off. It’s a clear indicator that India is becoming a major hub for high-quality electronics manufacturing. The ongoing reforms and incentives are creating a more conducive environment for both domestic and international players, which is crucial for long-term growth.

Anamika: Given these advancements, what do you think are the next steps for India to leverage its strengths and achieve greater heights in the electronics sector?

John: India’s strengths lie in its large, educated, and English-speaking workforce. To harness these strengths, the country needs to address ongoing infrastructure issues while also focusing on innovation and technological advancement. Creating an ecosystem that supports research and development, along with fostering public-private partnerships, will be key.

The electronics sector is integral to numerous industries, including automotive and aerospace. By continuing to build on these strengths and addressing infrastructure gaps, India can position itself as a global leader in electronics. Additionally, encouraging local startups and innovators will drive further growth and ensure the country remains at the forefront of technological advancements.

Anamika: Shifting to a broader perspective, you recently wrapped up an event in Malaysia. How do you assess the Asia-Pacific region’s influence on the global electronics industry compared to regions like the U.S. and Europe?

John: The Asia-Pacific region plays an increasingly dominant role in the global electronics industry. The scale of electronics manufacturing in Asia is unparalleled, with many of the world’s largest production facilities located here. This dominance is due in part to the region’s established infrastructure, skilled workforce, and cost-effective production capabilities.

In contrast, the U.S. and Europe are focusing more on high-end design and innovation. While these regions still lead in certain aspects of technology development, they rely heavily on Asia for large-scale manufacturing. The future of the electronics industry lies in collaboration across regions. It’s not about competition but rather about leveraging each region’s strengths to drive global advancements.

Anamika: The U.S. has recently seen a push towards reshoring industries, with initiatives like the CHIPS Act. How do you see these policy changes influencing the shift, and what gaps still need to be addressed?

John: The CHIPS Act is a significant move towards bolstering semiconductor production in the U.S. It highlights the government’s commitment to reducing dependency on foreign sources and enhancing domestic capabilities. However, building semiconductor plants is only one part of the equation. The broader infrastructure required to support these plants, including supply chains and skilled workforce development, is equally important.

Addressing these gaps will require a coordinated effort between government, industry, and educational institutions. While the CHIPS Act is a step in the right direction, the industry must also focus on creating a robust supply chain and ensuring that the workforce is adequately trained to support this growth. A comprehensive strategy that includes all these elements will be essential for achieving long-term success.

Anamika: With regard to the U.S. and Asia’s different focuses, where does the U.S. stand in terms of talent, and how does it compare to Asia’s manufacturing dominance?

John: The U.S. has traditionally excelled in high-end design, innovation, and research. However, when it comes to large-scale manufacturing, Asia has established a significant lead. The concentration of manufacturing talent and facilities in Asia is unmatched, particularly in countries like China, South Korea, and Taiwan.

The challenge for the U.S. is to bridge this gap by enhancing its manufacturing capabilities while continuing to lead in design and innovation. This requires investments in technology and infrastructure, as well as efforts to revitalize the domestic manufacturing workforce. By fostering a collaborative approach and leveraging strengths from both regions, the U.S. can aim to create a more balanced and resilient electronics industry.

Anamika: As IPC is involved in workforce development, what are the key challenges facing the global electronics talent pool, and how is IPC addressing these issues?

John: The global electronics talent pool faces several challenges, including geopolitical tensions, which can disrupt collaboration and trade. Tariffs, trade restrictions, and political conflicts can particularly impact smaller businesses that lack the resources to navigate these barriers.

At IPC, we address these challenges through various councils and committees dedicated to workforce development. Our efforts focus on promoting global knowledge sharing, enhancing skills training, and fostering partnerships between industry and academia. By maintaining open lines of communication and collaboration, we aim to support a healthy and innovative talent pool across regions.

Anamika: Geopolitical tensions, such as the ongoing “chip war,” have indeed affected the industry. In your opinion, who stands to win this race, and at what cost?

John: Viewing the situation as a “war” is counterproductive. Instead, the focus should be on innovation and collaboration. Countries that invest in long-term solutions and adopt a collaborative approach will fare better. A win in this context is not about outpacing others but rather about advancing technology and addressing global challenges like sustainability and efficiency.

Those who concentrate solely on short-term gains or exclusive strategies are likely to face challenges down the line. A collaborative, system-wide approach that integrates global expertise and resources will be crucial for achieving sustainable progress and technological advancement.

Anamika: Let’s discuss innovation and supply chain issues. How can the electronics industry tackle these challenges and foster new advancements amid current tensions?

John: Sustainability is a key area where the industry can find common ground. By investing in sustainable practices and technologies, companies can address supply chain issues and drive innovation. This includes developing new materials, improving energy efficiency, and enhancing recyclability.

AI is also a powerful tool for addressing supply chain challenges and advancing technology. It can optimize processes, predict inefficiencies, and drive innovation in chip design and manufacturing. Embracing AI and other emerging technologies will be crucial for making the electronics industry more efficient and sustainable in the long run.

Anamika: With AI’s potential for transforming the industry, how do you envision its role in enhancing energy efficiency and addressing environmental concerns?

John: AI has the potential to revolutionize energy efficiency in the electronics industry. It can analyze vast amounts of data to identify patterns and optimize energy usage across various systems. For example, AI can enhance the design of energy-efficient chips, improve manufacturing processes, and streamline supply chains.

In terms of environmental concerns, AI can aid in developing sustainable practices by optimizing resource usage and minimizing waste. It can also contribute to advancements in recycling technologies, ensuring that electronic waste is managed more effectively. By leveraging AI, the industry can make significant strides towards a more sustainable and eco-friendly future.