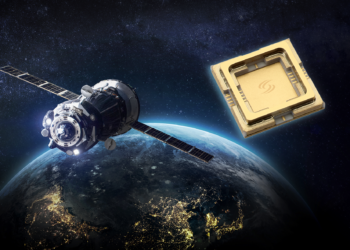

Rogers Corporation (NYSE:ROG) plans to build a new factory in China to manufacture its curamik AMB (Active Metal Brazed) and DBC (Direct Bonded Copper) substrates to meet significant demand growth. The first phase of the expansion is slated for completion in 2025. This follows last year’s investment in expanding the company’s curamik factory in Eschenbach, Germany.

“To better support our global customers and meet the growing demand for power substrates used in electric and hybrid electric vehicles (EV/HEV) and renewable energy applications, we are planning to build a new state-of-the-art factory in China. Upon completion, this new factory will help shorten lead times and deepen technical collaborations with customers in Asia,” said Jeff Tsao, Advanced Electronic Solutions (AES) Vice President and General Manager. “We have been a trusted partner to leading power module suppliers for decades, delivering efficient and reliable power semiconductor substrates, and today’s announcement further strengthens that position.”

This latest investment continues Rogers’ manufacturing strategy of positioning capacity to serve its global customer base. The company continues to focus on supporting growth opportunities across its markets with ongoing initiatives to drive capacity throughput improvements at existing facilities and make measured investments in new capacity. The expansion plan will be discussed in the company’s Q2 2023 earnings conference call, and any further developments will be communicated at that time. Rogers continues to expect capital expenditures for full-year 2023 to be in the range of $65 to $75 million.