Navitas Semiconductor and Compuware enter into a partnership to define new benchmarks for data center power supplies. Being notorious for high power consumption (electricity, power conversion & cooling), energy takes nearly 44% of a data center’s cost. An upgrade to GaN-based data centers could save over 15 TWhr or up to $1.9 billion per year, which represents a 6x return on investment in a year.

“GaN is a breakthrough new technology that is enabling dramatic reductions in size, energy savings and power density for data center power supplies,” said Robin Cheng, VP of Compuware’s R&D team. “Navitas is an excellent partner with industry-leading GaN IC technology that integrates GaN power, GaN drive, plus control and protection to widen our horizon of GaN and cooperate to create new, breakthrough standards for high-performance computing, as the world’s demand for data increases.”

Typical data centers using silicon to process power achieve only 75% end-to-end efficiency from ‘AC-to-processor’. A GaN-based data center is expected to reach 84%, representing a dramatic 36% increase in energy savings.

Since 2014, Compuware has introduced more ‘Titanium-certified’ power supplies than any other company. Over 1/3 of the highest-efficiency-grade models certified are from Compuware, and the company ships over 2,000,000 server power supplies each year, with Supermicro as a lead customer With an estimated $25 of GaN content per power supply, this represents a $50M per year opportunity.

The new benchmarks are not only enabled by GaN technology but also demanded by legislation such as the European Union’s ‘Directive 2009/125/EC, 2019 Annex’ which states that data new center power supplies must meet the extreme 80 Plus ‘Titanium’ level of efficiency from January 1st, 2023.

“Navitas and Compuware are aligned on extreme efficiency gains and critical environmental impact,” said Gene Sheridan, Navitas’ CEO and co-founder. “Together, I am confident we will set the efficiency, energy consumption and CO2 benchmarks for the industry with the future of GaN-based data centers.”

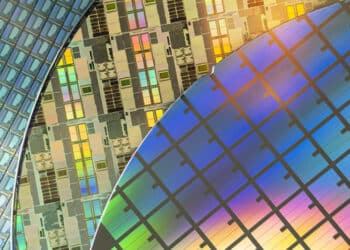

Manufacturing a GaN power IC has up to a 10x lower CO2 footprint than for a silicon chip, and when you also consider the use-case efficiency, material size and weight benefits, then together GaN can save 4 kg of CO2 for every GaN IC shipped. Overall, GaN is expected to address a 2.6 Gton / year reduction in CO2 emissions by 2050. With over 13 million servers shipped each year, each with over $75 of GaN content, data centers represent a ~$1 billion per year GaN opportunity.