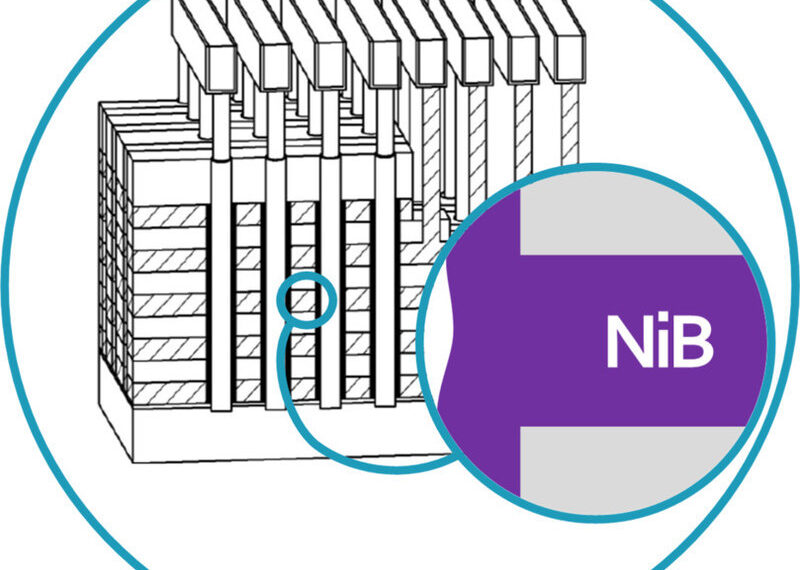

Saclay, France-based provider of metallization technologies for advanced logic and 3D NAND memory devices, aveni, SA secures a patent that can extend the industry standard of layers from 100 to 200+ layers on a single wafer for 3D NAND memory devices.

This becomes the single most important advancement in 3D NAND technology in more than 20 years.

This breakthrough in Nickel Boron (NiB) wet deposition was the result of years of research in the field of NiB metallization, where the company currently holds more than 60 patents. This latest patent and aveni “know how” further strengthens the company’s impressive product suite and enables companies in the semiconductor and other high-tech industries to lower costs and improve efficiency.

“For many years, the industry was looking for a way to address the challenge of finding a metal that could be applied and deposited on a complex topography,” said Frederic Raynal, Chief Technology Officer, aveni, SA. “aveni discovered that by using a wet process of chemistry, it was possible to metalize everywhere within the device, and create a solution that replaces the Tungsten and its Titanium Nitride (TiN) diffusion barrier with a Nickel Boron electro-less barrier. This unique formulation offers an unprecedented advantage for word line fill of 3D NAND structures, including bottom-up void free fill in small openings and conformal deposition in large openings.”

aveni is the only company on the market today that can offer this new technology, and is poised to dramatically impact global wafer production.

“We’ve known for years that Nickel Boron has the potential to revolutionize the semiconductor industry,” said Bruno Morel, CEO, aveni, SA. “There are three important factors that our latest patent features for 3D NAND technology: extendibility, improved process – from multiple steps to one-step – and truly limitless capabilities. These three factors represent a key differentiator for us and foreshadows a significant shift from the current industry standard, dry deposited Tungsten.”